Defect Detection on Ultra-Flat Wafers (Magic Mirror™)

The Hologenix Magic Mirror Inspection Method

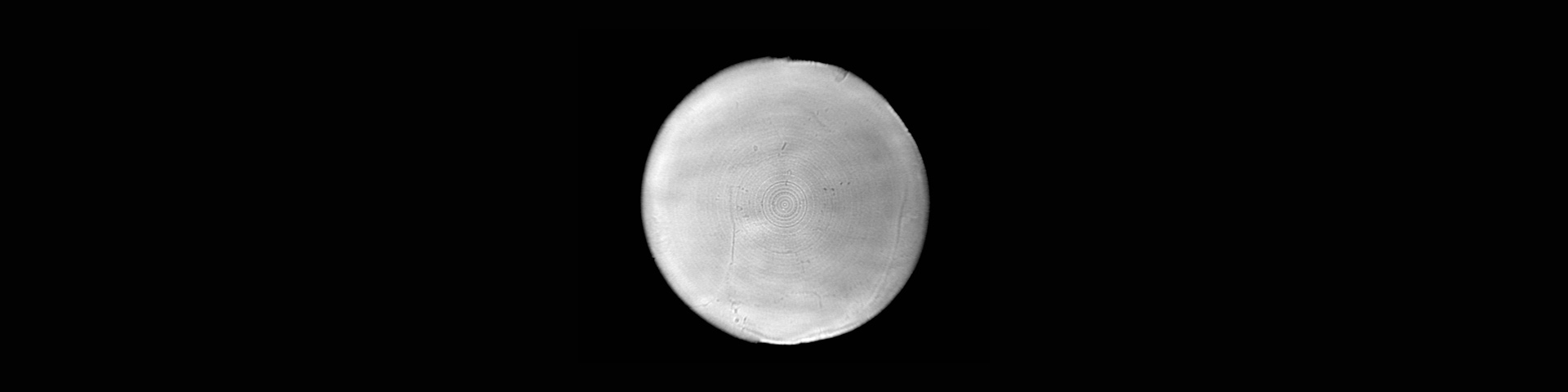

The Magic Mirror or Makyoh (meaning 'magic mirror' in Japanese) refers to a bronze mirror originating from ancient China that reflects an image to a distant wall when the Sun shines on the mirror. A relief pattern, resembling the projected image, is engraved on the back side of the mirror; no pattern can be seen on the front side by the naked eye.

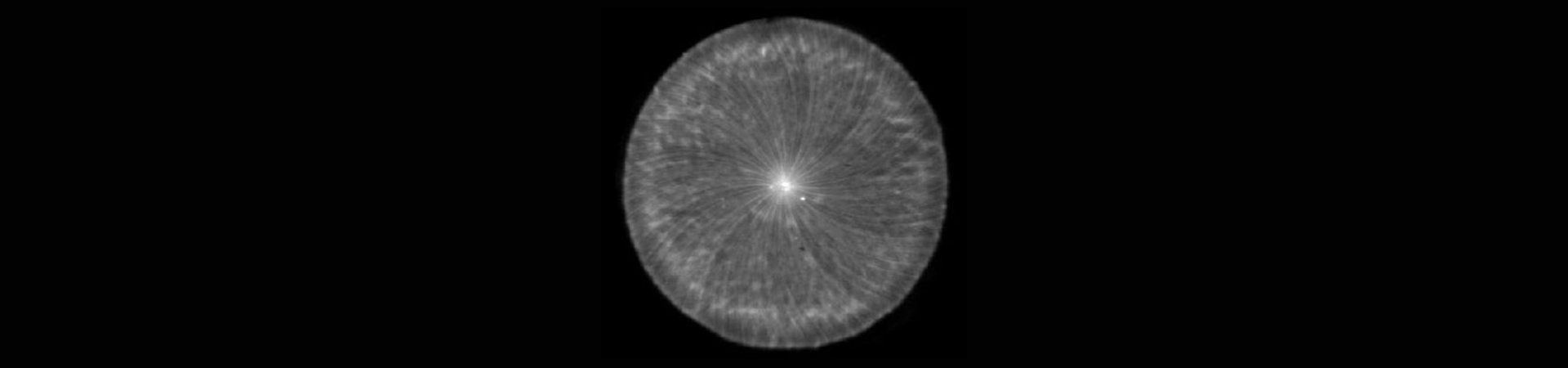

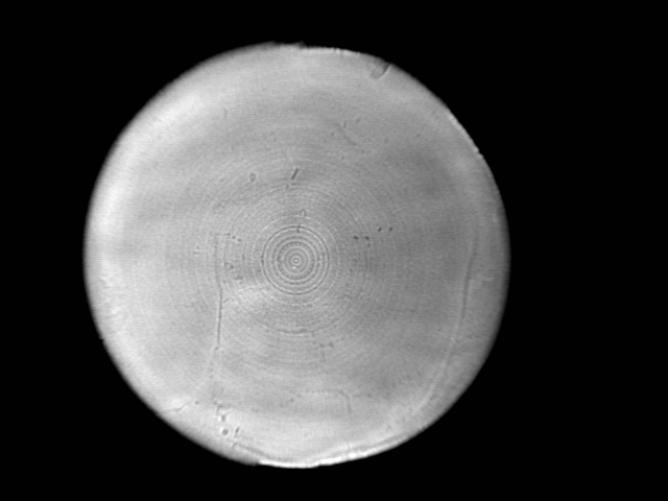

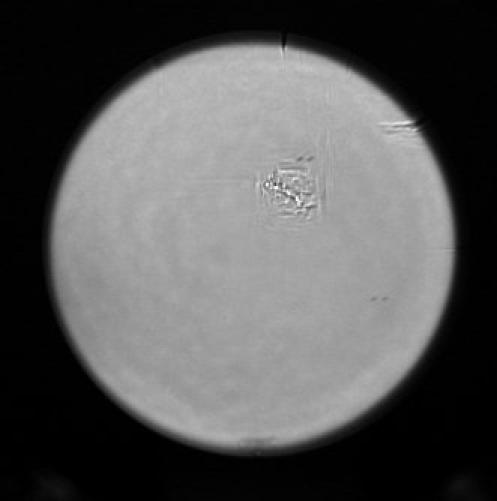

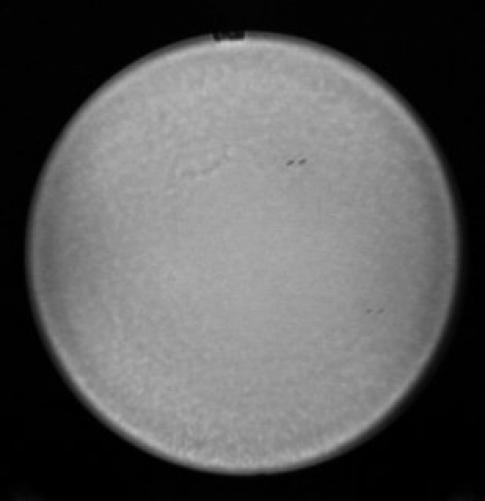

The 'magic' of the mirror can be understood using simple geometrical principles: the local irregularities of the reflecting surface act as concave or convex mirrors therefore a collimated light beam impinging on the surface produces an image on a screen that, to a certain extent, reflects the mirror's morphology. The front-face microdeformations (invisible to the naked eye) are caused by the stresses due to the engraved back image.

The Makyoh concept is a powerful topographic tool for the characterization of the morphology of glass and mirror-like surfaces, such as semiconductor wafers. The sensitivity of the method is a 0.4 μm height difference over a 10 mm distance and 50 nm over a 0.5 mm distance. Makyoh topography has proven its power, for example in detecting flaws induced by wafer slicing, polishing, lapping, and defects in directly bonded Si wafers.